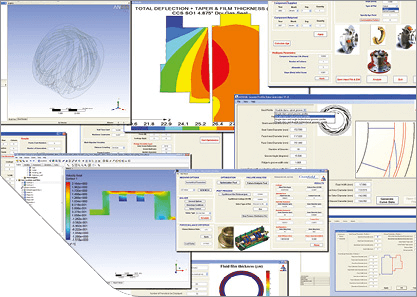

In the development of our mechanical seals, we use state-of-the-art simulation and CAX programs. This ensures the perfect function in the early development phase.

Among other things, we use self-developed simulation programs, finite element analysis (FEA) and computational fluid dynamics (CFD). Together with our extensive product validation and test program, our leading sealing technology is developed. All this to ensure that our customers' systems have a longer service life and fewer failures.